Return to previous page

High pressure hoses

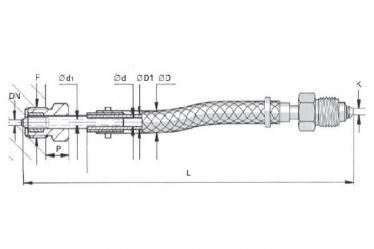

SITEC High-pressure hoses enable you to assemble high-pressure systems with flexible connections up to 3.200 bar ( 46.000 PSI ).

| Specifications | |

| Pressure | max. 3.200 bar / 46.000 PSI |

| Temperature | -10°C to +60°C |

Features and advantages

- High-pressure hoses enable you to assemble high-pressure systems with flexible connections up to 3,200 bar ( 46,000 PSI ).

- High-pressure hoses are ready for the assembly, supplied complete with high-pressure connectors, e.g. with gland nuts and collars on both ends.

- These high-pressure connectors may be installed directly into all HP components of the corresponding tube connection size.

- In the multilayer pressure hoses, the 4–8 spiral wound layers of plated high-strength steel around the flexible hose core serve as pressure support. To protect these spiral wound layers against mechanical damage, they are covered by another cover of non-abrasive material.

- The safety sleeves at both hose ends ensure a solid connection between high-pressure hose and connectors.

- Materials: Hose core Polyoxymethylene (POM) - Connecting nipples Stainless steel

- Operating temperature: – 10°C to + 60°C.

- The maximum operating pressure is depending on the process fluid. The following safety factor compared to the burst pressure are proposed:

SF=2.5: For water.

SF=4: For other liquids and for gases. - Important: The customer is responsible for the compliance with all local safety regulations!

- The indicated minimum bending radius must be observed.

- During the installation and in operation high-pressure hoses should not be kinked or stressed mechanically.

Options

- Models without protection cover (add “-O” to the part no.).

- Hose safety stockings for length L 1.5 m or more (add “-S” to the part no.)